Reaching deep into the My Car Quest Wayback Machine, from July 2014, I found this fascinating story about a man that really did design and build his own car. I know many car lovers have this dream but so few actually do it. The Comments are worth reading too, so I left them in place.

I hope you all enjoy this story – Part Two will be posted tomorrow.

Mike Gulett, Editor

by Raffi Minasian

History is littered with stories of independent car builders and their desires to build a car of their own. Few seldom make it past the drawing board; fewer still make it to a full sized car. It takes a certain blend of foolishness and determination to build a car from scratch. But if you can persevere, you get a car; a unique and lasting artifact of your youthful foolishness, a reminder of what it means to never give up on a dream.

I grew up in Southern California. I was a nerdy kid, pouring through car magazines, building models, and dreaming of cars. Living only a few miles from Shelby’s factory, Paxton Superchargers, and So Cal hot rods, it was the perfect place for a car crazy kid.

In 1978, most of my friends were hopping up Mustangs and Camaros. If you had some money you spent it on hot rodding your car (traction bars and Supershop goodies) or going to the beach to meet girls. Quirky car nuts like me took a chance on something exotic like an Alfa or Fiat. There were no cell phones, ipods, X boxes, or cable TV distracting you from the main goal in life…fixing cars and driving them. Well, OK also to meet girls.

By the time I was 17, I had purchased and re-sold a few cars with the goal of saving enough money to buy a Maserati or Ferrari. But another plan haunted me, to design and build my own car. I found a few copies of “Car Styling” magazine demonstrating how to use plaster, and our local library had books on fiberglass molding techniques.

It all seemed hauntingly simple; you get a donor car, strip the metal and then drop your newly formed body over the top and voila …new car, just like building the plastic AMT and Monogram models lining my bookshelves. I started drawing and planning, then built crude models. Dad, a fellow car nut, encouraged me to plan as much as I could on paper before spending any money.

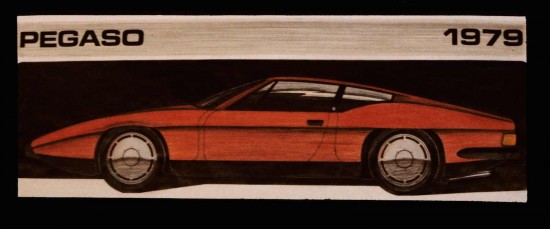

1969/1983 Pegaso American Twin Turbo

In February 1979 I met Bill Miller, the owner of the 1953 Pegaso “Thrill” and former owner of the Bill Miller Special as featured in a recent FF article. One day Bill and I started sharing ideas for building a new car. I showed Bill some drawings and we decided to start a full sized build. Neither of us really new where to start but Bill had some experience with racing cars and had run a machine shop so he knew his way around casting and fabrication. Between the two of us we had a running start on some of the technical aspects, but the design was something different.

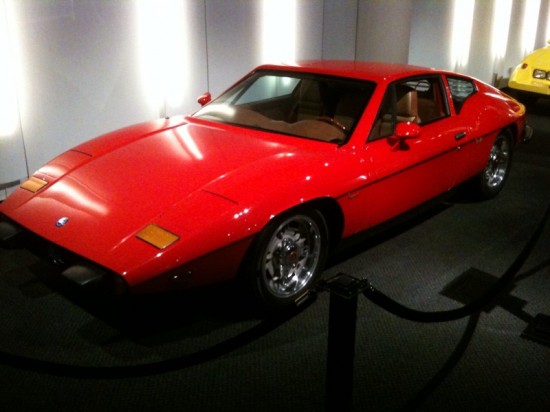

Bill and I liked the look of classic 60’s sports cars so we decided on a car with a familiar but fresh “look”. Retro before retro was “in”. The theme became “what if Pegaso had built a car to compete with the very first super cars – the Ferrari Daytona and Lamborghini Miura.”

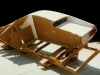

What followed were several stages of development until deciding on a fiberglass, mid-engine layout with fastback styling. Bill and I were fans of the Muira, Pantera, and Italian coachbuilt cars so we worked in this genre. The first thing we did was layout a body centerline and five main section planes made from half inch bent metal wire.

Once we had the basic layout of the body we covered it in chicken wire and began laying plaster. After a few days we discovered that plaster and chicken wire was a mistake.

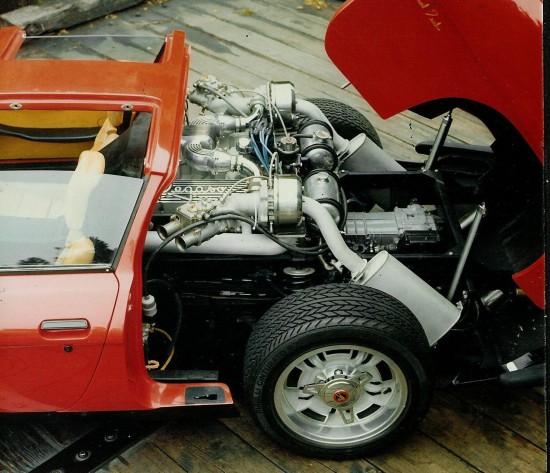

It never stopped warping. Concurrently we purchased a 914 from a junkyard and pealed away all the body panels and much of the inner structure. We adapted brakes, wheels and tires, and installed a Buick aluminum V8 with four Webers.

This drivable platform and wire form body seduced us into thinking we were months away from a completed car. It was summer of 1979 and I had just been accepted to study at UCLA. “What a great car to drive to campus” I dreamily thought. Little did I know I would earn a bachelors degree sooner than completing this car.

Returning to the study of the warping chicken wire body, Bill and I took a closer look at other car design books. We needed a solid buck to form the body. We built a skeleton from plywood and Celutex, which was bendable but rigid enough to make the basic form of the body.

We increased the number of section planes until we had a solid ‘car-shaped’ loaf of car-shaped bread made up of wood and Celutex slices.

We then skim coated the contours in plaster, like icing a cake. This method worked far better than the chicken wire, however, when summer had passed and the rains began, cracks appeared in our plaster form. At first we filled the little ones in and moved on. But newer and larger ones returned like demons in the night. We filled and filled, sanded and reshaped, but the moisture was insatiable. Desperate for relief, we advance to a fiberglass splash mold.

By early spring, Dick Kilgroe (a local boat repair and manufacturer) joined the project. Dick worked with us creating the splash mold and main body molds, agreeing to teach as we went along. We used low cost construction methods, coating the plaster with mold release and hand laminating sections of fiberglass while matting in cardboard tubes (paper towel, Christmas wrapper tubes, and toilet paper role tubes) cut in half as splash-mold reinforcements.

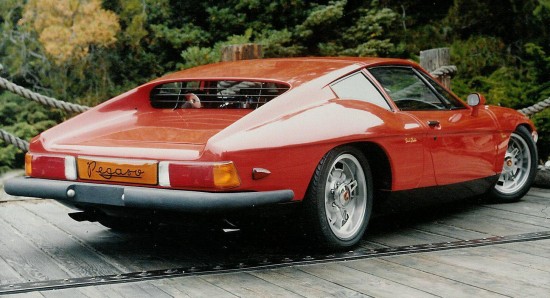

Once done, we inverted the shell master and laminated a new body shell. The new shell was more stable than the fickle plaster so we fine tuned the surface and cut the body into three sections. We added doors, headlight doors, trunk, and removable t-top seams.

Once all the body panels were completed, we built the “strike faces”. Every body part needed edge details, hinges, latches, and complex inner support structure. Because all the parts opened up, all of it had to be finished like the outside body surface.

In a production automobile, the most complex component is the door. We researched production doors and tried our best to use an existing inner structure. In the end, like so much of this car, we had to build it ourselves. We did use some GM parts.

The outside door handles were taken from Ford sedans, the inner door latch came from GM, but cast our own handles. In all, the door mechanism took more than three months to complete and assemble and then reassemble for paint and interior trim, at least three times in order to get it right.

The side glass was contoured to our plaster molds and the rear window was made from three layers of clear plastic (for sound insulation). The windshield, donated by an Audi Fox, was perhaps the easiest item to build into the body. With exception of the tail light assemblies (taken from 1979 BMW 320i), side view mirrors (GM), Toyota Supra headlight buckets and mechanism, and an aftermarket radio antenna, every part on the exterior surface was hand made.

All interior pieces were carved in plaster and fiberglass molds were made to create the structure for the leather wrapping. The dash and center console panels were made of steam bent plywood and laminated with a thin layer of burled walnut, then clear coated with protective lacquer. The seats were originally to be donated by Recaro for promotional purposes as part of the build.

They sent us a working set of seat frames but it was too late. We mistakenly built the inner bucket frames too small. There was no aftermarket adjustable seat that would fit.

The only choice was to use the thin fiberglass construction seat frames from the 914 and create our own seat cushions. Using fiberglass and plaster (by now we were masters at these materials) we constructed individual pressurized seat cushion molds and injected two-part foam to make cushions. The steering column (used from a ‘78 Buick), Nardi Steering wheel, dash buttons, and misc. original style Pegaso instruments were the only parts in the interior that were not hand made or substantially modified for our needs.

As work progressed, we advanced to another layer of delusional myopia; other people might want to buy one. I had visited with Arntz, Clenet, and Vector to see how they were building cars. It seemed there was potential for a car like this in the market. I didn’t think we needed to go as far as Vector in the technology department, but I also didn’t want to build a kit car. Shipping a custom car like this should be just as easy as any Antique Car & Classic Car Transport.

With the right engineering and practical applications I was confident we could produce a car in limited numbers. I proposed to my father that with the right financial support we could produce the car for roughly $40K and sell for $65K.

The plan required investment capitol of $30K to complete the prototype. My father asked me which I was going to be on the breakfast plate, the pig or the chicken. Uncertain as to his analogy, I paused. Dad replied, “the pig is committed to breakfast, the chicken is participating”.

I said good-bye to my Ferrari dream money and never laid eggs again.

More photos are in the slide show below.

###

Let us know what you think in the Comments.

THE AUTHOR: Raffi Minasian is a freelance designer working with a wide variety of clients. He holds a BFA from University of California at Los Angeles in Product Design and a BS in Transportation Design from Art Center College. His experience includes aircraft interior design for The Boeing Corporation, toys for Mattel and McDonald’s, consumer products for Microsoft, Polaris, and Rainbird, and car designs for Toyota, Subaru, The Franklin Mint, and Moal Coachbuilders. Over the past twenty years Raffi has designed more than 300 different model cars, and hundreds of consumer products, toys, and home accessories.

~ Terrific article, thanks for posting,Mike and Raffi. I will anxiously wait for tomorrow’s episode.

~ Mike, I can’t seem to get the ‘like’ or ‘share’ functions to work for facebook.

What a FABULOUS story. The story of building your car is wonderful, but even more is your determination to get it done. It is a story of human accomplishment. My respect and admiration. And a SUPER car too!!

Scot – try it now it seems to be working again.

~ Thanks, Mike. I posted it on Coachbuilding & Concepts using just the URL, which worked and drew enthusiastic response. Within half an hour I had notifications that you’d posted it on a couple pager as well, with the same excellent comments. I’ve always enjoyed your daily emails, Mike, and this one as much as any!

Thanks for the nice comments on this car. It still excites me today every time I walk into my garage.

I hope to take it to shows in the coming years.

Raffi, thanks for the inspiring story. Now, enthusiasts, you can understand why (and how) Milt Brown and Ron Plescia were driven to create and produce the Apollo GT. As the times were different then, fortunately they were able to put it into series production with 88 hand-built examples coming off the line. Ron told me that when he saw the first production Apollo body (car no. 1003) coming off the boat in Oakland, he was almost speechless. He just couldn’t believe that his drawings had become reality.

Raffi, I only wish that your Pegaso could have gotten as far!

Robb Northrup

Pres, Apollo Owners Registry

Thanks Robb,

Milt and Ron built a great car. One that I have admired for many years and gotten close to owning. They certainly did what so few people have been able to do independently. In part 2 of this article there will be more information on the production plans and what we had hoped to accomplish. Still, even with only one in my garage, I do appreciate that feeling Ron expressed seeing it every time.

Thanks for your comments.

What a wonderful story about a terrific project and a beautiful automobile that YOU created, Raffi. Be proud. I’m glad that I helped to restore several old cars over the years, but you CREATED one. Tip’o the hat to you, my friend. Bestowing it with the “Pegaso” name was very nice, too. 🙂

Raffi….what a great story and a wonderful car. The step-by-step review of what you did certainly harks back to the 40s and 50s in building your own car. Your story would make every one of those guys (and families) proud. And…I’m glad to hear you still have the car. That’s something I rarely find in our research, so keep this car a legacy in your family – for all future generations to cherish.

Geoff Hacker

Forgotten Fiberglass

Raffi, You were a dreamers dreamer. For a kid and 1982 your Pegaso was an incredible effort with beautiful result.I applaud your tenacity,especially after all the problems you encountered. Beautiful details !

Greg Bailey studiospeciale.net

RAFFI WHAT A WONDERFUL STORY I HAVE BEEN KICKING AROUND FIBERGLASS CARS ALL MY LIFE AND I SO ADMIRE GUYS LIKE YOURSELF THAT STICK WITH IT AND SEE A PROJECT THRU—NEAT STUFF —-THANKS FF —–KAZ

Thanks Geoff, Greg, and Dennis – I appreciate the comments on this project. Hoping to do more in the coming years with new projects involving other passionate car people.

~ We are all hoping [and willing to support] more extraordinary accomplishments! Grt’r’done!

Raffi, I am in awe! You accomplished far beyond what we aspired to do at Victress. Your account of your tribulations with the ever-moving surface of your mockup brings back memories; they are similar to the problems we had doing the full scale clay S-4 in a metal building with no temperature control! I’m looking forward to the next chapter.

Merrill

Merrill, I am flattered by your comments!! I have always thought of the work you had done at Victress as THE fiberglass innovators in the American Composite Coachwork Era. NIce of you to include me in the community I learned so much from when studying to do my project.

Hmm! Wonder where that first line came from?

I grew up living next door to Bill Miller and his wife, Lupe (who was best friends with my mom). I remember helping Uncle Bill and Raffi build the Pegaso. Uncle Bill would have me sanding the fiberglass or other simple tasks but I thought it was amazing to help with such an awesome car. I was a young girl but the memories have lasted my entire life. This was a wonderful article that brought back precious memories.

Hi Cheryl,

Nice to read this comment. Those days were long ago but I too remember them. Bill was always kind to anyone who wanted to learn. Lupe used to make us some great food for lunch. So sad when she died. Bill was crushed and his niece Kate (who lived with them for some time) was just devastated. A lot of life circled around that project with 4+ years. Nice to read your comments and reconnect on those memories.

Try this story , the difference is a 3 million poor people country instead of living in the USA and thousands of dollars less budget .

http://www.automovilsport.com/historia/dellepius/nota.html

http://www.collectioncar.com/detailed.php?ad=14410&category_id=1

Aldo

Fantastic car! Do you still have the moulds?

I may have missed this story in 2014, about the time I started reading MCQ.

Beautiful design. Absolutely incredible outcome for a home made project. Building a soap box derby car or a go-cart, back in the late 1950’s and early 1960’s, was a big deal in my neighborhood. Talk about the notion of “dreaming big”!

Do you still have the car, is it fully sorted out and CA registered/smogged? I’m looking forward to part #2.

I enjoyed the story and wonder–when you got those other design jobs with automakers , was this in your portfolio? If I were the Human Resources man, I’d be glad to see proof you followed through to a running car on one of your design ideas.

Hey Raffi! How interesting this shows up now after we talked last week. I’m sure your design (like your ‘stash!) will turn out to be timeless! 😎 Great effort, thanks again and look forward to have you drop in again and show you the crazy car we talked about.