As promised here is Part Two from the My Car Quest Wayback Machine, from July 2014. Part One was posted yesterday and is available at this link.

Mike Gulett, Editor

by Raffi Minasian

The Los Angeles Auto Expo in 1982

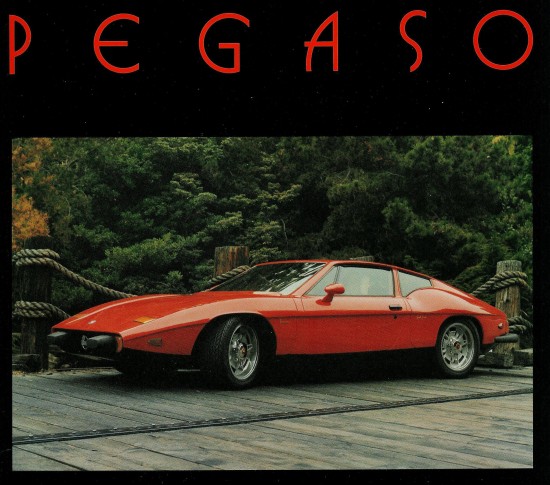

We proposed to complete the car in time for the Los Angeles Auto Expo in 1982, where we would display the car, hand out brochures and (once again in a flurry of delusion) take orders. But it was clear that making a hand built automobile with the use of stripped Porsche 914s and Buick engine parts had some problems. So we began a whole new layout using a hand made chassis powered by the tried and true 350 V8 and the newest in engine boosting…twin turbos.

Plans for a twin cam aluminum engine with all wheel drive were one of the many ideas Bill and I tossed about as what might have been part of the Pegaso technology at the time. But it was far too expensive for us to attempt to make our own drive train. Somewhere in my archives are drawings for this engine and the unique layout that Bill and I imagined if funds were not an issue.

Around the time I presented the plan to my father, we also began to shop renderings and photos of the car in progress to various aftermarket companies and potential investors. Some donated parts, others donated services like machining, painting, and plating. To start construction of the frame, we hired a full time assistant and all-around mechanic, Bob Bojorquez.

Bob was a manager at one of the local Standard Brands paint stores. He sold us enough fiberglass resin to make Noahs Arc so he figure out we were up to something. One visit to our makeshift shop and he was in. Bob kept Bill and me evened out on issues where we disagreed on design and finish. After years of starts and stops Bill and I had become frustrated. Bob’s sense of humor was one of the best things to revive the spirit of the project.

The engine itself was not unique so we hand made valve covers complete with Pegaso script, utilized a twin turbo set up that was developed for marine engines, and modified it to accept twin side draft Webers. Because of the unique configuration and limited engine room.

We had little space remaining for standard headers. Once again it was time to hand make those items. Bill and I figured it would take two years to build the car. That might have been, if we didn’t have to do everything two to three times to get it right.

When you are restoring a car, it comes with some assembly history. With a good manual and nice photos to start with, a restoration project can be organized very well. But a whole car with nothing to guide you leaves you with time intensive trial and error as your only real guide.

Among the many different parts and features that we experimented with was an on board air compressor system that used engine vacuum to generate pressurized air which filled the side rails of the frame as air tanks. This compressed air would supply pressure to the front and rear pistons used to open and close the body sections. This elaborate rigging of tubes, valves, switching contacts, and 8 pistons was engineered completely by Bill.

While it finally performed a wonderful display of high tech access, it was unreliable and had no manual override.

Other novel features included motorized adjustable clutch, brake and gas pedals to accommodate longer legged drivers, removable T-top sections, twin gas tanks, pop up headlights (mechanism borrowed from a Toyota Supra), and our own cast and polished wheels.

Preparing for the final days of assembly we engaged Joe Leweck to prepare and paint the car. Much of our efforts in building and testing the various body panels would come back to haunt us as we assembled the car for the final showing. There were many repaint sessions and touch ups as we moved closer to the finish line.

Nearly five years after our first encounter and that disastrous chicken wire frame, Bill, Bob, and I winched the finished prototype onto a car carrier for delivery to the 1983 Los Angeles Auto Expo.

The journey to craft this car was one of late nights, long summer days, and shoestring budgets. Anyone who knew me at that time (my future wife included) knew this car was my #1 priority. For four long years, virtually every life event was squeezed around my build schedule.

That the prototype exists at all and remains in my collection today is remarkable since I completed it when I was 21 years old.

More than a quarter century has passed since the unveiling in Los Angeles. Over the years I have revised and continually improved the car in an effort to update and refine it for safe road use. The challenge remains to maintain the integrity of the original design while pursuing the goal of a safe driving vehicle.

Among the many items that were left undone included a fuse box, production based electrical system, a working key starting ignition, reasonable access to the engine manually if the air system was down, and a host of other details. Much of the continued work was done in the late 80’s by good friend Dick Donnelly who revised and updating much of the aspects that had been “the best we could do” at the time.

In the late 90’s (when I lived in PA) I shipped the car to Treasured Motorcar Services in Maryland and we removed the old JFZ racing brakes and replaced them with a new system.

We also removed the front spare tire and replaced it with a single FuelSafe gas tank, doing away with the old twin tank design from the somewhat questionable location flanking the engine.

Although the original plan to build a series of 500 limited production cars was never achieved, we took orders at the auto show for 14 cars. Three production versions of the prototype were started before we determined it was simply too much effort to make the dream become production. Though we researched safety and highway laws for limited production cars, we needed to revise our plans in order to truly build a car for sale to the public.

In our last effort to revise the production based build plan, we lengthened the front of the car (from firewall to front wheel center) and dropped body shells on top of the then state of the art Corvette, but the look was never as nice as the tight mid engine package with the front and rear drop off styling that we felt made the car so aggressive.

As time passed Bill and I realized there was no real way for us to build these cars and make any money. While it had been fun to see what we could do with the resources, exercising dreams on a large scale can get to be expensive both personally and financially. Although it was a once in a lifetime project I had realized it was time to get serious if I wanted to have a career in car design.

That year I enrolled at the Art Center College of Design and received the formal training to become a professional car designer.

For me the Pegaso will always be a complex personal journey. I had no idea it would become a lifelong project, but it continues to inspire me the more I work on it. Although the car has seen limited use in the past twenty years (most of the miles covered with a dealer plate or on a rented race track for tests and shakedown), I simply enjoy seeing it parked in my garage.

In the years since, I have worked with hot rod shops, restoration teams, custom car shops, model car companies, and manufactured thousands of parts for the automotive aftermarket and restoration business.

Although I learned a vast amount of fabrication and engineering from the Pegaso, I would never do it again. Today the amount of aftermarket parts that are superbly engineered and refined for home built cars boggles the mind. A complete Cobra based chassis can be purchased and delivered to your home for less than $25k.

Complete 400hp crate motors are available for under $5k, and four custom wheels can be CNC cut to the highest level of finish and mounted in DOT approved hoops for the price of ONE questionable hand casted wheel.

To do this type of project today would be a wonderful coordination and specification exercise bringing together professionally engineered parts and pieces toward a completed running chassis and then focusing on the best part of all, sculpting a beautiful and well proportioned body.

While it was a yearning of my youth to build something completely and fully realized as an automobile, it seems daunting today with a family, a design practice, and other professional priorities. There is something about the eternal optimism of youth, the trumping effect of enthusiasm over reality, and the lack of real world understanding that drove me to complete this project.

Although it has been channeled into other ventures, lately there have been a few drawings and plans that seem to be pinned to my garage wall.

I find myself chatting with Cobra replica people and spending way too much time reading engine specs. But then cars do that to you. They get under your skin and make you do things that have little to do with reason and balance.

Just like when I was 16 and fell for that haunting voice pushing me further into the creative stream… “I wonder what it will look like going down the road?”

Let us know what you think in the Comments.

More photos are in the slide show below.

###

THE AUTHOR: Raffi Minasian is an award winning artist and published illustrator, Raffi has taught illustration and design at several noted universities. In 2003 after holding positions as Senior Director and Vice President for major corporations, he returned to his roots as a “hands on” designer working on freelance projects. Today, in addition to his ongoing product design work, Raffi manufactures specialty parts for the classic and muscle car aftermarket as well as custom parts for hot rods and customs.

One of the better stories I have read here. Great reading and a cool car.

Great story. Still an impressive looking car. Deserves much better than might have been,

Hi Julian

are you Julian McNamara the journalist writing in Auto Classic a story about a Lister-Jaguar? If so, I would like to speak to you. Here is my mail: jacques.samalens@icloud.com

Best regards,

JS

Thanks for the kind comments. It’s been a great journey, ongoing and satisfying in every way.

Raffi, this is beyond a story, it is an odyssey! I can speak from some experience, having built my own sports car (a Byers SR-100) to completion starting at about age 14. It took more than 3 1/2 years to complete, using mostly hand tools and an electric drill, but when finished, sported a full interior, full weather protection including custom fiberglass hardtop, heater, radio, and full instrumentation and a hand fabricated African mahogany dash. I drove it everywhere for about three years before a Pontiac GTO tri-power 4-speed came into my life.

I have always believed that when you’re 14 or 15 years old, you don’t yet know what you can’t do. Had I been a couple of years older when I dreamed of building my own car pretty much from scratch, I would surely have known that it was too daunting a task! Great story and I’m thrilled for you that you still have the car.

For those of you interested in learning more about Rollie Langston’s Byers SR-100 build, you can click on the link below:

http://www.forgottenfiberglass.com/?s=rollie&x=0&y=0

It’s quite a story – he started working on this car at age 14. Both Raffi and Rollie are true adventurers in handcrafted automobiles.

Geoff Hacker

Forgotten Fiberglass

Wonderful story, Raffi. I’m so pleased that you still have the car, and that it has been a lifetime project.

Merrill

Your car is absolutely stunning, and I really enjoyed the story. Having been through this process myself (I designed a retro-styled sports car called the Varsity Roadster) I remember encountering many of the same challenges you faced. That perspective gives me a unique appreciation for your amazing accomplishment. Your styling looks good from all angles…this is something that many production cars can’t achieve. Your fit and finish are very tight, and I know how much time and attention to detail that requires. Last but not least, you have doors that open and close and that have roll up door glass! There are precious few independent built one-off sports cars that actually become drivers, and yours appears to be one of the nicest ones out there. Great job! Unlike most cars on the road today (in my opinion) you have built a true work of art.

Very nice complements Ted, Rollie, and Merrill. As builders yourselves, you know the challenges personally in this obsessive fraternity. Means all the more coming from those who have scaled the same terrain and emerged with an artifact of excellence!!

Raffi is not only incredibly talented as a designer but as a very fine musician as well, then there is that he is an amazingly kind and nice gentleman, who I am proud to call friend… we have done several projects together and it is always a pleasure working with him. Great to see a wonderful tribute written about him…

Thanks for sharing such an interesting and personal story.