by Wallace Wyss –

In attempting to discover how Tesla came out of nowhere and became the world’s largest EV maker, I discovered the magic word is something like “Insource”. My definition–you get what you need from what you already have. During the Russian invasion of the Ukraine, when I read that the US gets something like 12% of its oil from Russia I was wondering “Why?” when there’s plenty of oil underground in the US, Canada and Mexico.

Couple that with the shortage of computer chips and the shortage of the precious metals to make EV batteries and I realize all our present shortages are due to one word: outsourcing.

Oh, I know the temptation to outsource was there–politicians got elected by cutting off pipelines, by refusing permits to drill, and it was so much easier to source oil offshore. And as far as critical parts, I wonder how many employees at Stellantis, (nee Chrysler), Ford and GM got promoted when they triumphantly returned from a overseas business meeting and announced “Hey, I got a helluva deal signed in (You name the country) they’re going to make all our whatchacallits at half what we’re payin’ to make them in the U.S..”

So they went off that evening, having received a bonus, to celebrate at the Bloomfield Open Hunt Club or Grosse Point Yacht Club. But now, years later, we are suffering stateside because we farmed out so many key parts outside the U.S, that now the Big Three can’t complete their cars and trucks.

Going into the shortages, it is becoming abundantly clear that too much auto making in America depended on parts coming from an offshore supplier. When a chip maker in Japan had a factory fire a couple years ago, more than a dozen automakers worldwide were left with no back-up sources. Ford F150s began to fill up fields in Detroit because they were sourcing a tiny chip from Japan, Taiwan, Vietnam, you name it. Plus a lot of offshore suppliers were down on production because of the virus.

Then came the war (so far confined to the Ukraine). The worse part about it was the political implications of the US sourcing oil from a country that was no longer simpatico with us. Buying oil from Russia at the same time you are supplying weapons to the Ukrainians fighting Russia for their freedom, or having to buy oil from Iran, who held US diplomats prisoners, or Venezuela where the dictator grabbed US businesses and nationalized them makes us look stupid. We shouldn’t have to do that when the US has millions of barrels oil in reserve.

I think the example of Tesla should be looked at. True, Tesla makes lots of cars in China, and now Berlin, (over 500,000 units at each plant) both offshore to be sure. But April 7th 2022 will see one helluva a party as Musk celebrates opening the Austin, TX plant in the good ol’ USA. He can make an equal amount of cars in either Shanghai or Austin. Should the US get in a political tiff with Red China, and they shut down Tesla’s plant in Shanghai, it would choke off Tesla’s world production by 25% but at least they could still fill orders. He wisely doesn’t put all his eggs in one basket.

Tesla had trouble getting chips but notice they quietly bought chip making firms and battery making firms. They still fulfilled their production quota, when The Big Three had to park an unending row of cars and trucks outside in fields that couldn’t be finished because of outsourcing problems, mostly lack of chips.

It reminds one of the undue credit given for decades in business schools to W. Edwards Deming, a much celebrated business sage of the last century who advocated the just-in-time philosophy. His mantra was “Why stack thousands of parts for cars coming down the line when you can have them arrive just-in-time?” Sounds logical, right? The problem is, in the real world, there are glitches in shipping. Or a regional war. Oh, not to forget a disease. Covid came Stateside for sure, but once the serum became available, it was minimized.

So Deming’s concept, which once sounded so logical, was more something for an ideal world, one where there are no diseases, no strikes, and no shipping backlogs. Business professors worshipped the wrong God.

In sum I’d say I would take all those guys (and gals) who got promoted at their job for making a good deal outsourcing parts for American cars and trucks and require them to take a mandatory course in which they have to look at America and see what resources haven’t been looked at–in both men and materials. Sources that can be developed in the good old USA. Those out-sourcers got promoted each time they scored a money-saving deal for their employers but, when one of the Big Three goes under because of too much outsourcing and a resultant breakdown in the supply chain, the American taxpayers will again be asked to bail them out, and it will eventually be conceded how foolish they were to go along with outsourcing in the first place.

The ultimate insult, (which is spelled out in my book in the GM chapter) is when GM accepted over $80 billion in bailouts from American taxpayers in 2008 to avoid bankruptcy only to invest in partnerships in China instead of building new facilities or electric cars in the USA. They took American’s money to build up competitors to America’s products.

And so it is. We might be able to keep American car manufacturing going even with all the delays but we will be a healthier nation business-wise if we cut down on outsourcing as much as possible. And let’s change what they are teaching in business school–their models no longer work in our current world.

A staple of Elon Musk’s business philosophy is vertical integration. In one of his company’s third quarter Shareholder Letters, Musk mentioned his “in-sourcing” strategy. His goal from the beginning was to practice it more than The Big Three. Rather than use the same old machines the Big Three always used, he invested in internal manufacturing technology by building the machines he needed. His philosophy was to first ask: “Okay, guys, what are the things we want to make?” Once that was answered, his marching orders were “Design a machine that will make that thing.”

One can see how this caused consternation at the Big Three. A VP in charge of manufacturing at one of their factories can’t order his underling, “Go out and buy a machine like Tesla has” because, in many cases, nobody makes machines like that. Sure you could order one up, but if you use Tesla’s ideas you’d have to pay a licensing fee.

Musk delights in all this, often saying “We made the machine, that made the machine that made the machine,” ad infinitum.

Let us know what you think in the Comments.

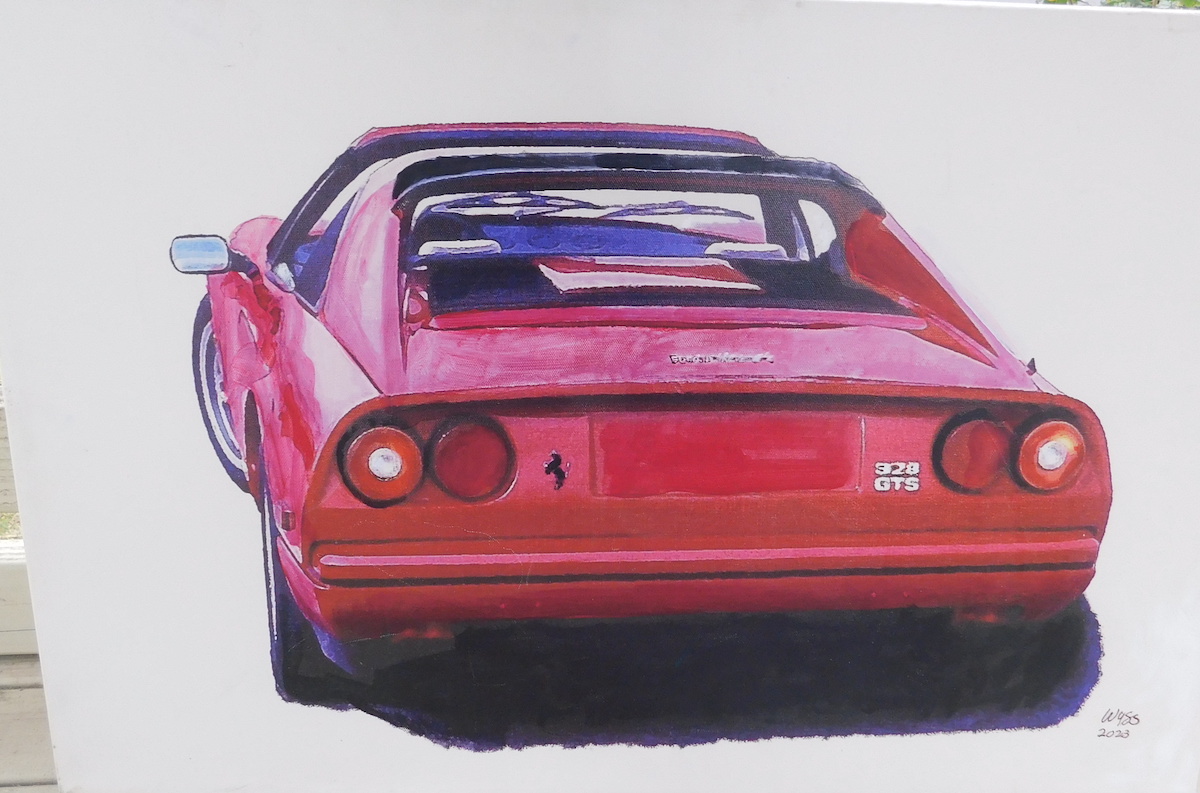

THE AUTHOR Wallace Wyss is readying a book called How Tesla Killed Detroit.

Copyright 2022 – Wallace Wyss

It all started with NAFTA, and then when Mexico wasn’t cheap enough for the corporate overlords, they made sure that China got Most Favored Nation Trade Status, to ensure that they could outsource the other 85% they didn’t already outsource to Mexico. Forget about cars and consumer appliances. When the pandemic was at its peak here in NYC, and the doctors and nurses had to wear black garbage bags as PPE, because it was all made in China, you saw how low this country has fallen. These are most definitely the Late, Great United States. The only job engines that this country wants to pursue are gambling and weed – I mean the ‘gaming” and ‘cannabis’ industries. God help us all. Glenn in Brooklyn, NY.

Glenn Krasner, agreed

Amen! Agree with all written wholeheartedly. While many people deride former President Trump, like him or not, one thing he was 100% right about was insourcing. As a nation, so many industries (also, our government, Wall Street, and consumers wanting the least expensive goods) are to blame for the overall pickle we are in. Shoes, furniture, metals, clothing and so many industries that it would take a long time to list, outsourced production to China, Vietnam, India, Bangladesh, and many other countries in the Third World. This has resulted in the elimination of many good manufacturing jobs here in the U.S. which jobs resulted in the huge middle class this Country used to have. So now, many of those good middle class jobs are gone and benefiting those other countries and their citizens and raising their standard of living while ours is far less than it used to be…witness the huge increase in homelessness, drug addiction and other societal ills we have now that did not exist just a few decades ago. We need to bring back the ability to manufacture those automotive chips, the shoes, textiles, furniture, drug ingredients, etc. Covid proved how vulnerable we are to shortages of needed health care products let alone food production. Why pay our farmers not to produce crops when we are facing possible food shortages due to the Russia-Ukraine war? Why not make the U.S. oil independent like it was when Trump was in office? We need the jobs here in the U.S. so that we can invigorate our middle class.

Rob,

We use to manufacture 2/3 of the world’s computer chips – we basically invented computer technology – now, we only manufacture 1/3 of the world’s chips, hence supply chain problems. Intel said they were now going to open 2 new chip plants in the US, but it took the pandemic supply chain problems to convince them to do it, after outsourcing the bulk of their chip production to Singapore and Malaysia for many, many years..

Glenn in Brooklyn, NY.

Glenn, thanks for the info. Great if they build new chip plants here. Production of most of our consumable items needs to come back on shore. We are sitting ducks for Countries that can, at a whim (such as China) wreak havoc in our Country as has been happening for the past few years. Do U.S. based companies improve their profit margins with cheap overseas labor? Absolutely! But at what overall cost to our society so that people can get cheaply made clothes, shoes or other products. David Muir on ABC News has a “Made in America” segment that showcases companies making products here in the U.S. Nice to see these stories, however, manufacturing has to come back here on a huge scale so that we are never dependent again on other countries, or vulnerable to health pandemics, war or other unforeseen situations that put us all at risk.

Love of Country and the welfare of its citizens should Trump (pardon the pun) the profits of corporations or those politicians on the take (on either side of the aisle) who put their Interests ahead of their constituents.

Ford gets a lot of praise for being an American automaker responding to the Tesla threat with the Mach E electric crossover. But most of the time the media glosses over the fact the Mach-E r is built at the Cuautitlan Stamping and Assembly Plant in Mexico. I yearn for the days when American cars were built in the US of A. Oh, and they’re going to start building them in China as well.

Elon Musk makes cars in China too, but in my mind made up for it with two US plants. He did America a great favor when he eschewed using Russian boosters for his space effort. Imsgine where the US would be now if our space effort still depended on the Russians?

It was truly pathetic that when NASA retired the Space Shuttle Orbiter that we had to depend on Soyuz boosters to launch our satellites into space for many years. A new low for our country. Besides Musk’s SpaceX, Boeing has a new SLS program to launch satellites into space for NASA. For athletic shoes, New Balance is the last footwear company that still makes some of its line here in the USA. Glenn in Brooklyn, NY.

I have tried to imagine the state of affairs if we cut China trade because if you go to Costco, Walmart, etc., it seems like 99% of everything for sale is Made in China. The shelves would be bare. And if you consider something simple like a can opener that is 99 cents at the 99 cents store, in America a can opener maker couldn’t even buy the metal to make a can opener for 99 cents! It’s amazing that America thinks up a lot of inventions, like computers and cellphones, but farms production all out overseas and now when the American auto industry needs chips because we don’t have domestic chip manufacturers, we can’t finish our vehicles,…,,the horror!

Now I haven’t been to a Detroit automaker’s factory for decades but this drone video of the newest Tesla fctory looks ike something from Mars–robots building robot cars. Where’s the humans?

https://insideevs.com/news/576308/amazing-drone-footage-shows-tesla-model-y-made-giga-berlin/?utm_source=Master%20List&utm_medium=email&utm_campaign=IEV_US_20220329_InsideEVsNewsletter%20%28YmP33K%29&_kx=e0H-qO_GmlUfUOJtSPiOSdZHrgxT6FB5DoogNNfVyAY%3D.VCGm8F